-

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service.

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service. -

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific.

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific. -

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

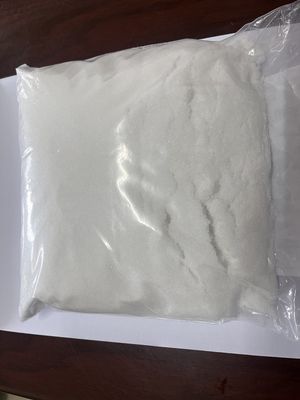

Anti-hydrolysis agent Plastic Additive N,N'-Bis(2.6-diisopropylphenyl)carbodiimide monomer carbodiimide for PU TPU PLA PBAT PPC PHAs

| Name | N,N'-Bis(2.6-diisopropylphenyl)carbodiimide | Abbreviated Name | STABILIZER 7000 |

|---|---|---|---|

| CAS | 2162-74-5 | Appearance | White Crystalline Powder |

| Purity | ≥ 99.0% | MF | C25H34N2 |

| MW | 362.56 | Application | Anti-hydrolysis Agent Plastic Additive Hydrolysis Stabilizer |

| Highlight | Anti-hydrolysis agent Plastic Additive,N,N'-Bis(2.6-diisopropylphenyl)carbodiimide,monomer carbodiimide for PU |

||

Anti-hydrolysis agent Plastic Additive N,N'-Bis(2.6-diisopropylphenyl)carbodiimide is a monomer carbodiimide for polyester polyurethanes(PU and TPU) and biodegradable resins like PLA PBAT PPC PHAs.

Specification of Anti-hydrolysis agent Plastic Additive N,N'-Bis(2.6-diisopropylphenyl)carbodiimide

| CAS | 2162-74-5 |

| Color | White crystalline powder |

| Purity | ≥99.0% |

| MF | C25H34N2 |

| MW | 362.56 |

| Application | PET,PBT,PA,CO-PET,PU,TPU,CPU,TPEE,EVA,PLA,PHA,PBS,PTT |

Description of Anti-hydrolysis agent Plastic Additive N,N'-Bis(2.6-diisopropylphenyl)carbodiimide

This product is a representative monomeric carbodiimide-based hydrolysis stabilizer, widely used in:

• Condensation polymers: including polyester polyols, nylons, PET/PBT engineering plastics

• Polyurethane systems: elastomers (PU, TPU, CPU), adhesives and coatings

• Lubricant esters

Functioning as an effective hydrolysis inhibitor for PET, PBT, PA, CO-PET, PU, TPU, CPU, TPEE, EVA, PLA, PHA, PBS and PTT materials, it provides:

✓ Hydrolysis resistance - Prevents mechanical property degradation caused by hydrolysis

✓ End-group stabilization - Blocks reactive carboxyl terminals in polyesters

✓ Material restoration - Repairs hydrolytically damaged polyester/polyurethane chains

The stabilizer significantly extends service life of polymer products under demanding conditions (high temperature/humidity), ensuring long-term performance stability.

[Technical features]

• Monomolecular structure for uniform distribution

• Excellent thermal stability

• Broad material compatibility

• Non-interfering with processing parameters

Usage Guidelines of Anti-hydrolysis agent Plastic Additive N,N'-Bis(2.6-diisopropylphenyl)carbodiimide

1. Polyurethane (PU) Systems:

Dosage: 1.0 wt% (based on polyester polyol weight)

Method: Directly add to the polyol component and mix thoroughly.

2. Cast Polyurethane (CPU):

Dosage: 1.0–2.5 wt% (based on prepolymer weight)

Method: Melt and incorporate into the prepolymer with sufficient stirring for uniform dispersion.

3. Adhesives:

Dosage: 1.0–3.0 wt% (based on solid content)

4. PET & PBT:

Dosage: 0.5–2.0 wt%

Benefits:

Enhances storage stability

Improves hydrolysis resistance by 3–7 times

5. Monofilament Fibers & Nylon Products:

Dosage: 0.5–3.0 wt%

Key Advantages:

✔ Easy incorporation into various polymer systems

✔ Significant extension of material lifespan under hydrolytic conditions

✔ Maintains processing stability without adverse effects

(Note: Optimal dosage may vary depending on specific formulations and application requirements.)

FAQ

Q1: What is your regular lead time for sample and official order?

A1: Sample lead time 5-7 days. Official order lead time 14-21 days.

Q2: What is your MOQ?

A2: MOQ usually is 1kg.

Q3: How you control product quality?

A3: From raw material inspection, dupro inspection to final product inspection are executed strictly.

Q4: What is your warranty policy?

A4: We will send you a new batch if there is any quality issue during warranty time

Q5: Do you refund if customer receive defective product and do not accept replacement?

A5: Yes