-

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service.

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service. -

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific.

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific. -

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

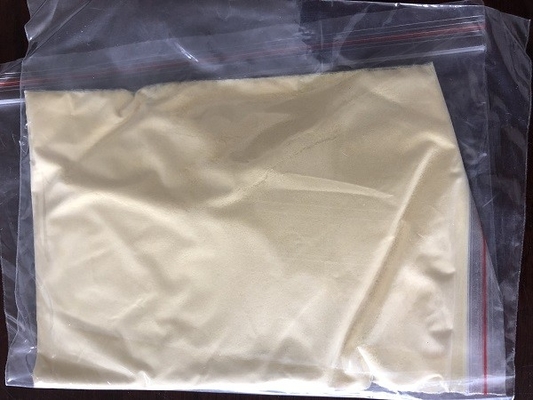

CAS 3006-93-7 Rubber Coating Material PDM N,N'-M-Phenylenedimaleimide

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| M. F. | C14H8N2O4 | M. W. | 268.23 |

|---|---|---|---|

| Purity | 99% | Appearance | Yellow Powder |

| CAS | 3006-93-7 | Application | Multi-purpose Rubber Agent |

| Highlight | PDM Rubber Coating Material,CAS 3006-93-7 Rubber Coating Material,N N'-M-Phenylenedimaleimide |

||

PDM N,N'-m-Phenylenedimaleimide CAS 3006-93-7 Rubber Coating Material

Specification

| CAS | 3006-93-7 |

| Purity | 99% |

| MF | C14H8N2O4 |

| MW | 268.23 |

| Appearance | yellow powder |

| Application | multi-purpose rubber agent |

Description

HVA-2 serves as multi-purpose rubber agent. It can not only work as curing agent in the processing of rubber, but also work as assistant curing agent for peroxide system and resistant-carbonization agent and adhesion agent tackifier. It can be applied for general rubber, as well as special rubber and rubber-plastic hybrid system.

It can be applied with sulphur for natural rubber to prevent sulfidation return, improve heat endurance decrease heat production , prevent aging, increase the adhesion strength between rubber and twister and the modulus of colloid sulfide. It can be applied in rubbers such as shoulder colloid of mobile load tires, cushion cord breaker and resolve the difficult problem on shoulder space of skew tires of heavy load mobiles. It can also be used for large specification products of natural rubber and various rubber products.

HVA-2 works as assistant curing agent for special rubbers like neoprene,chloiosulfuric polythene rubber,butyl benzene rubber,nitrile rubber,isovaleric ethelene rubber,butyl rubber,brominating butyl rubber,acrylic ester rubber,silicic rubber and rubber-plastic combined colloid, to significantly improve the properties of connection, the property of heat endurance. It is suitable for the class of high temperature rubbers, and it can significantly decrease permanent compression deformation. It can even decrease the consumption of peroxide, prevent the rubber material from burning in the processing. In addition, it can improve the adhesion strength between rubber material and twister and metals.

HVA-2 is non-sulphur curing agent . It can be applied for cable rubber. It can replace sulphur curing agent such as thiazole,thiuram etc., thus solve the difficult problem that when the copper lead comes into contact with copper electric appliances copper sulfide will be produced and it will pollute environment.

amount of consumption: 0.5-1.0 set when used as resistant-carbonization agent; 2-3 sets when used as curing agent ; 1.5 sets when used to improve the property of compression deformation; 0.5-5.0 sets when used to improve adhesion strength.

Advantages

1. Quick lead time

2. Low MOQ

3. Quality assured with COA

4. Full experience in shipping

5. Free consulting service

6. custom service welcome

FAQ

Q1: What is your regular lead time for sample and official order?

A1: Sample lead time 5-7 days. Official order lead time 14-21 days.

Q2: What is your MOQ?

A2: MOQ usually is 1kg.

Q3: How you control product quality?

A3: From raw material inspection, dupro inspection to final product inspection are executed strictly.

Q4: What is your warranty policy?

A4: We will send you a new batch if there is any quality issue during warranty time

Q5: Do you refund if customer receive defective product and do not accept replacement?

A5: Yes

Item Photo

![]()

![]()