-

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service.

Lara Schenk from BelgiumIt is Amazing that Feiming service exceed our expectation, really professional on consulting, customising, delivery, after-sale service. -

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific.

Steven from the USAFeiming can supply a variety of high performance material with sufficient inventory, service is really terrific. -

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

Kurt from SwitzerlandEverything is fine and the people are working on it . When I have some news I will share that then directly with you.

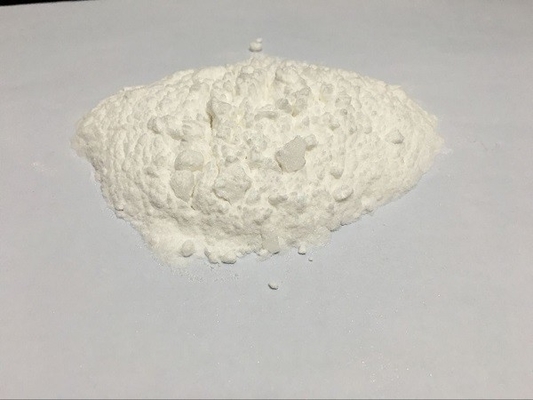

CAS 140-73-8 Rubber Coating Material N,N'-Dicinnamylidene-1,6-Hexanediamine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| M. F. | C24H28N2 | M. W. | 344.49 |

|---|---|---|---|

| Purity | 99.0% | Appearance | Light Yellow Or Milky White Powder |

| CAS | 140-73-8 | Application | Fluoro Gum Vulcanization Agent |

| Highlight | 140-73-8 Rubber Coating Material,COA Rubber Coating Material,CAS 140-73-8 |

||

N,N'-Dicinnamylidene-1,6-hexanediamine CAS # 140-73-8 Rubber Coating Material

Specification

| CAS | 140-73-8 |

| Purity | 99.0% |

| MF | C24H28N2 |

| MW | 344.49 |

| Appearance | light yellow or milky white powder |

| Application | fluoro gum vulcanization agent |

Description

Properties:light yellor or milky white powder,cinnamon fragrance,can dissolve in alcohol and ethyl ether,sg1.09,melting point 76-85℃.dry product has long resting period,not easy to be oxidized.

Uses:For fluoro gum vulcanization agent,good vulca-nized rubber performance.It can avoid vulcaized rubber producing air aperture.The dosage are 2~3parts in carbon black rubber,3~4parts in mineral loading material rubber.Usually(Ⅰ)molding vulcanize 30 mins.at 149℃; (Ⅱ)hot air vulcanize 24h.at 204℃.

Feature:use advance technology,no water or ethanol in product,high purity,low impurity content.won’t deteriorate for long resting period, so has good vulcanization effect.

Advantages

1. Quick lead time

2. Low MOQ

3. Quality assured with COA

4. Full experience in shipping

5. Free consulting service

6. custom service welcome

FAQ

Q1: What is your regular lead time for sample and official order?

A1: Sample lead time 5-7 days. Official order lead time 14-21 days.

Q2: What is your MOQ?

A2: MOQ usually is 1kg.

Q3: How you control product quality?

A3: From raw material inspection, dupro inspection to final product inspection are executed strictly.

Q4: What is your warranty policy?

A4: We will send you a new batch if there is any quality issue during warranty time

Q5: Do you refund if customer receive defective product and do not accept replacement?

A5: Yes

Item Photo

![]()

![]()